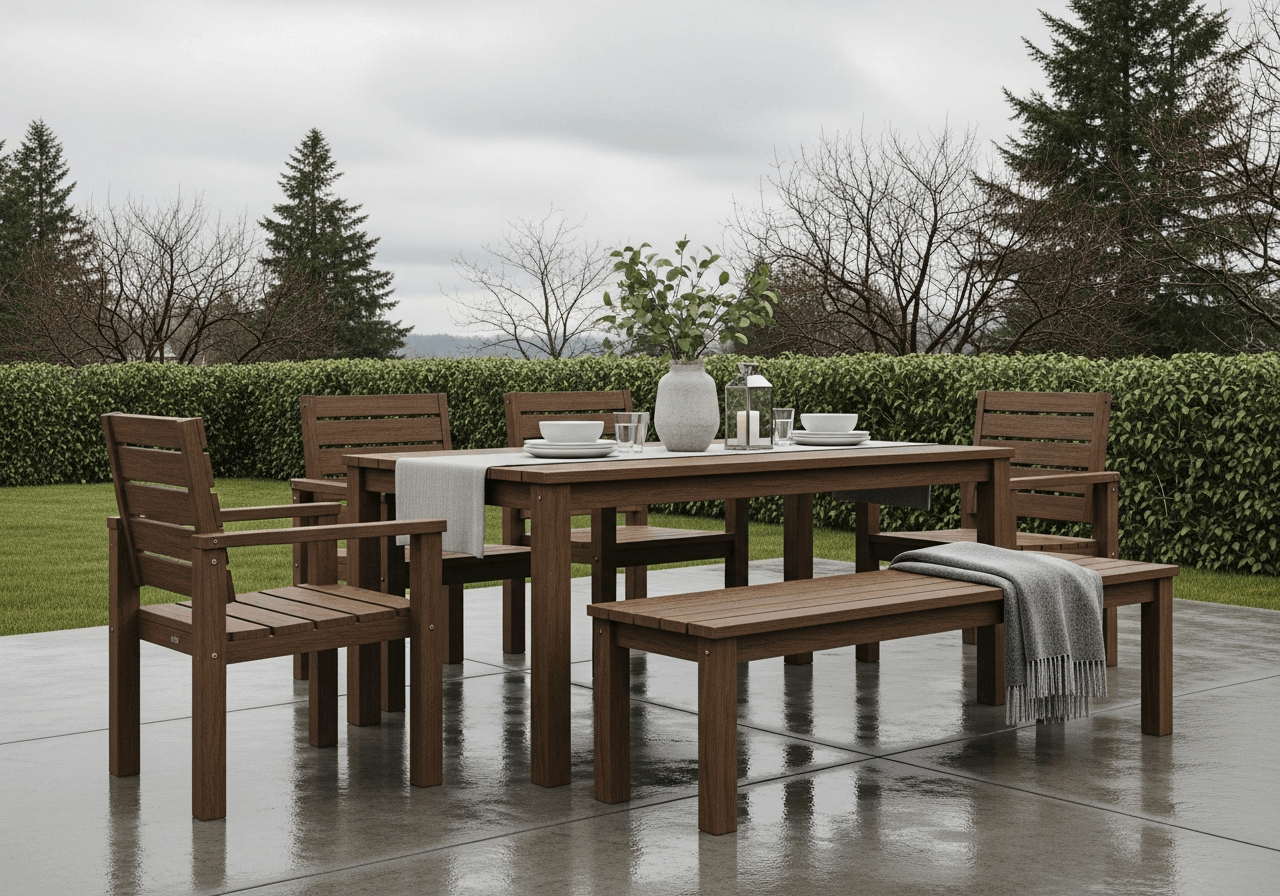

A cold-and-rainy climate solution: material fit, mass production, cross-border delivery, and launch assets in one program.

Challenge: prior supplier lacked durability; returns at 22%; lead time >60 days—peak season missed.

Timeline: Days 1–5 material fit → Days 6–35 sample-to-mass → Days 36–45 cross-border delivery (Vancouver port).

Sales: 6 SKUs launched, 1,500+ units in season; seasonal revenue C$310K.

Quality & Ops: returns down to 1.2%; client added 2 seasonal lines and signed an annual agreement; 800+ reviews citing “durability / natural texture”.

1、Material fit: moisture control, finish strategy, care guidelines for ironwood in cold-wet cycles.

2、Engineering: expansion gaps & drainage, reinforcement on stress points, anti-rust hardware & joints.

3、Sample-to-mass: parallelized production with packaging & transport plans to minimize damage and moisture issues.

4、Cross-border delivery: customs documentation and port-to-warehouse coordination to catch the sales window.

5、Content assets: outdoor lifestyle & detail shots, install & care videos, material cards to reduce misuse-driven returns.

1、Material fit & validation report|engineering/installation drawings|packaging plan & test records.

2、Mass production & delivery cadence|content pack (images / short videos / care guide).

3、Customs paperwork & inbound coordination

1,500+ units sold in season; revenue C$310K.

Returns reduced to 1.2%; after-sales workload cut significantly.

Client extended with 2 seasonal lines and an annual partnership; strong user feedback on durability & feel.